Building by building, floor by floor, coil by coil, Facilities Management (FM) staff have been painstakingly preparing for the annual switch from heating to cooling on two of Īꔄtv‚Äôs four campuses.

Many buildings on the Carleton and Studley campuses are heated and cooled using a large underground system of pipes that stretch for kilometres. These pipes start from the steam plant inside the Central Services Building (CSB).Őż

It‚Äôs a precise operation‚ÄĒand everything depends on the weather.

‚ÄúThe timing is the crucial part,‚ÄĚ says Roger Lloy, the plant manager. ‚ÄúEvery fall and spring we get warm days and cool nights, and we need consistent nighttime temperatures before we can make the big switch.‚ÄĚ

(What about Dal’s other campuses and buildings? More on that later.)

How it works

Consistency in temperature is needed to make sure equipment is protected from freezing, which would cause leaks and failure. This equipment includes cooling towers, piping and cooling coils in buildings.

There are four cooling towers on top of the central building. They hold 75,000 liters of water that flows through machines called chillers to remove heat picked up by refrigerant from a separate loop of water circulating around the campus

There are four cooling towers on top of the central building. They hold 75,000 liters of water that flows through machines called chillers to remove heat picked up by refrigerant from a separate loop of water circulating around the campus

That other loop contains 340,000 liters of water ‚ÄĒ about 1,300 bathtubs worth! ‚ÄĒ that travels through more than four kilometers of pipes. It goes into buildings, picks up heat from the air (like a radiator), and then returns to the plant to be cooled again. This process runs nonstop to keep the buildings cool. If the system needs repairs, it can take up to 5 days just to drain and refill all that water.

Shown right:ŐżTwo of the four chillers on top of the Central Service Building.

Once the weather turns favourable, FM staff ‚ÄĒ including plumbers, steamfitters, HVAC technicians (heating, ventilation, and air conditioning specialists), and building systems engineers ‚ÄĒ carefully check all the cooling equipment in each building that gets cold water. This inspection takes one to two weeks.

‚ÄúThe work is different in almost every building,‚ÄĚ explains Tim Hubley, HVAC supervisor. ‚ÄúThe cooling equipment hasn‚Äôt been used since the fall, so our crews look for leaks and follow a checklist, making repairs as needed.‚ÄĚ

We are the size of a small city, with over 160 individual buildings

Similar work happens in the underground tunnels, originally built in 1970. These tunnels don‚Äôt just carry cold water for cooling. They also have pipes for hot water used year-round in some buildings, and for steam, which heats buildings in the colder months ‚ÄĒ in addition to the high-voltage electrical cabling that distributes power throughout the university.

In early May, there is usually a steam-system shutdown. This gives the water time to cool down so crews can safely check and repair the underground equipment. This timing is planned with the needs of key buildings that rely on steam, like the Dalplex pool, the Aquatron research facility, and student residences, where hot water is needed for showers and heating.

Once all the equipment is confirmed ready, the chillers are switched on.

Then FM crews go back into the buildings again, checking for any new leaks or problems.

‚ÄúĪꔄtv is really an amazing place. We are the size of a small city, with over 160 individual buildings,‚ÄĚ says Craig Arthur, assistant vice president of Facilities Management. ‚ÄúNo one really understands how critical our central plants and systems are to our campuses or how much work it takes to keep these systems running efficiently.‚ÄĚ

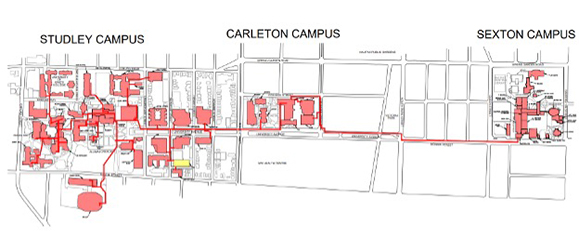

Above: Buildings cooled by the Central Services Building.

Thanks for your patience . . .

Once the chillers are turned on, the effects aren’t immediate.

For example, in the 15-storey Tupper Building, it takes longer for the chilled water to reach and cool the top floors. That’s partly because of how high the water has to travel and because those top floors get more sunlight, which makes them hotter.

The equipment also varies in age from building to building. Some systems are newer and more efficient, while others are older and more difficult to control.

Every spring and fall, FM gets dozens of calls from staff, students, and faculty wondering why their classrooms or offices feel too hot or too cold. Roger Lloy says patience is important.

Just like in your house or car, one day you have the heat on and the next you open a window

‚ÄúJust like in your house or car, one day you have the heat on and the next you open a window. While we work through these steps, we ask that people dress in layers, open windows when possible, and be patient.‚ÄĚ

The exact date the cooling system turns on changes each year, depending on the weather. But it’s usually working by mid-May and always before convocation. That way, the Rebecca Cohn Auditorium is comfortable for the 19 graduation ceremonies.

Then, just five months later in October, the entire process is done in reverse. The chillers are emptied, the pipes are drained, and the crews go building by building for another one to two weeks.

This part is especially important: Every drop of water must be removed before winter. If any water is left in the pipes and it freezes, the pipes can burst. That can cause floods and millions of dollars in damage.

Above: Buildings heated by the Central Services Building.

What about the other buildings?

Not every building on the Studley and Carleton campuses uses the central plant for cooling. Many newer buildings have standalone systems, which means each one has its own smaller cooling setup. Some very old buildings can’t be upgraded for modern air conditioning.

On Sexton Campus, cooling is managed building by building. But most of the heating still comes from the Central Services Building. In fact, the CSB also heats several buildings that aren‚Äôt even part of Īꔄtv, like the National Research Council, University of King‚Äôs College, And even the provincial Law Courts on Spring Garden Road.

On the Agricultural Campus, heat comes from a recently upgraded biomass co-generation plant. This plant uses waste wood chips as fuel, creating both heat for the campus and electricity for the grid. It has even won international praise for how energy-efficient it is.